January 9, 2019

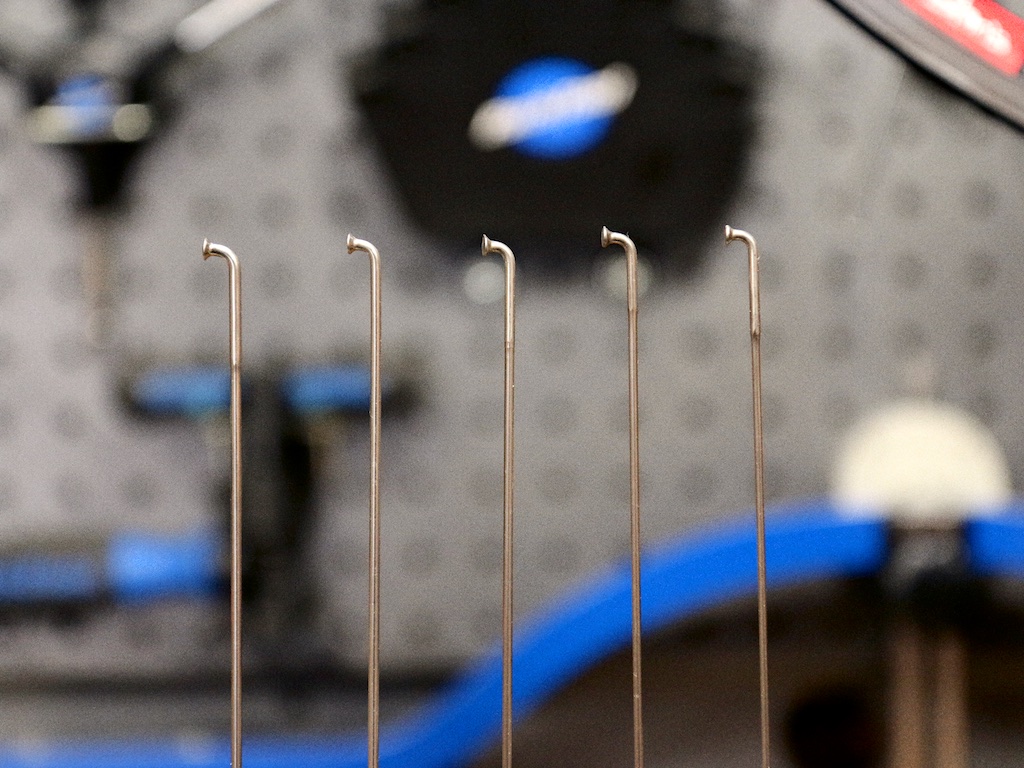

The correct spoke length is one that penetrates the nipple just right — not below the screwdriver flats and not past the top of the nipple. You don’t want to go too short because spoke threads reinforce nipples internally. Nipples, particularly aluminum nipples, have higher failure rates when paired with short spokes. You don’t want to go too long either. I define too long as past the end of the nipple. This is strictly true for some nipples however many can tolerate a couple turns past the end without issue. Turning past this baked-in limit causes nipple threads to grind into the unthreaded spoke shank, which creates a weakness in the spoke and is associated with spoke breakage.

The rounding part

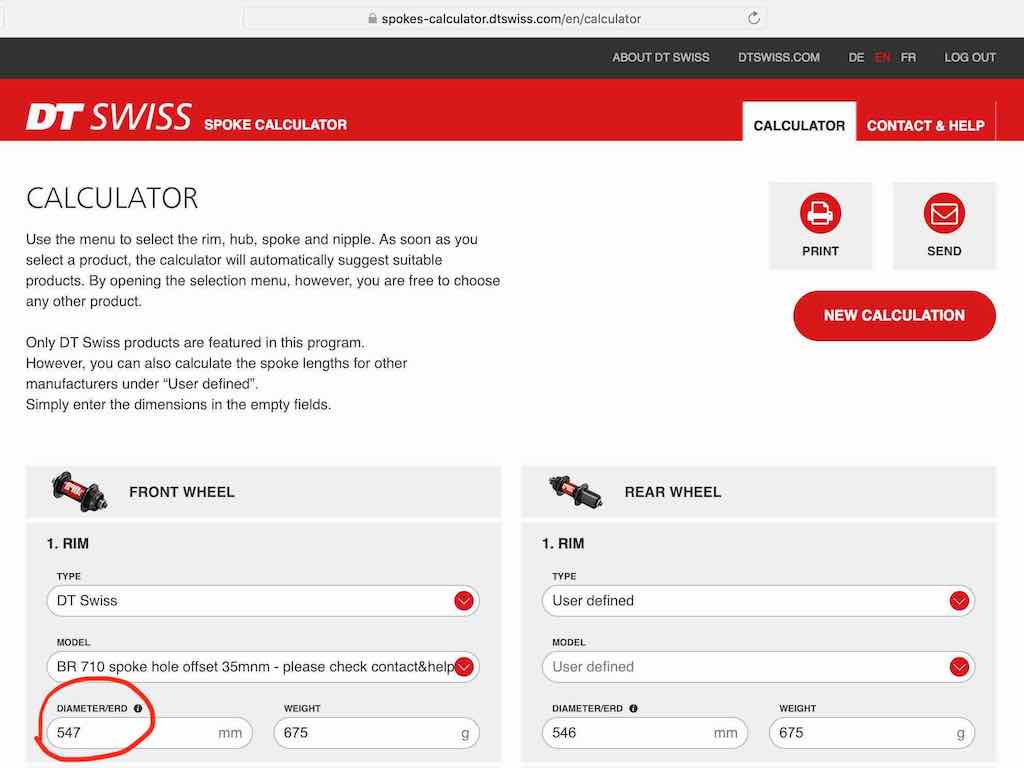

Spoke length calculators output lengths to the tenth of a millimetre, which must be rounded to match available supply. There’s no universal rounding algorithm because it depends on how you calculate spoke lengths in the first place. It depends on ERD measurement technique.

In my process I use measuring tools based on theoretical spoke penetration to the bottom of the nipple screwdriver slot. I don’t want my actual spoke penetration to be short of this mark, so I’m cautious about rounding down. My baseline is rounding to the nearest millimetre. If my target tension for a spoke is high, say 125kgf / 1200N, I’m not bothered rounding down as much as 0.6mm. This is because spokes stretch a fraction under tension and stretch is more pronounced at high tension. This logic particularly applies to thinner spokes because thinner spokes are more elastic. The opposite holds as well — a spoke built to 60kgf could be rounded up 0.6mm. As an example when building a rim brake rear wheel, where tension is quite imbalanced between sides, a wheelbuilder might round up on the low tension side and down on the high tension side if both lengths are halfway between sizes.

(Hopefully you can see this rounding logic doesn’t make sense if your theoretical spoke length targets the end of the nipple. In that case you would rarely round up.)

Traditionally spokes are stocked in two millimetre increments, which invites compromises depending on your calculated lengths. You can be forced to reckon with the the risks of going too short or too long. Maybe the uncertainty steers you to brass nipples instead of aluminum. Maybe it causes you to pick up nipple washers as an insurance policy. Bottom line: it’s not doing you any favours and to build the best wheels you ought to shop in one millimetre increments.