True from the joint

August 31, 2021

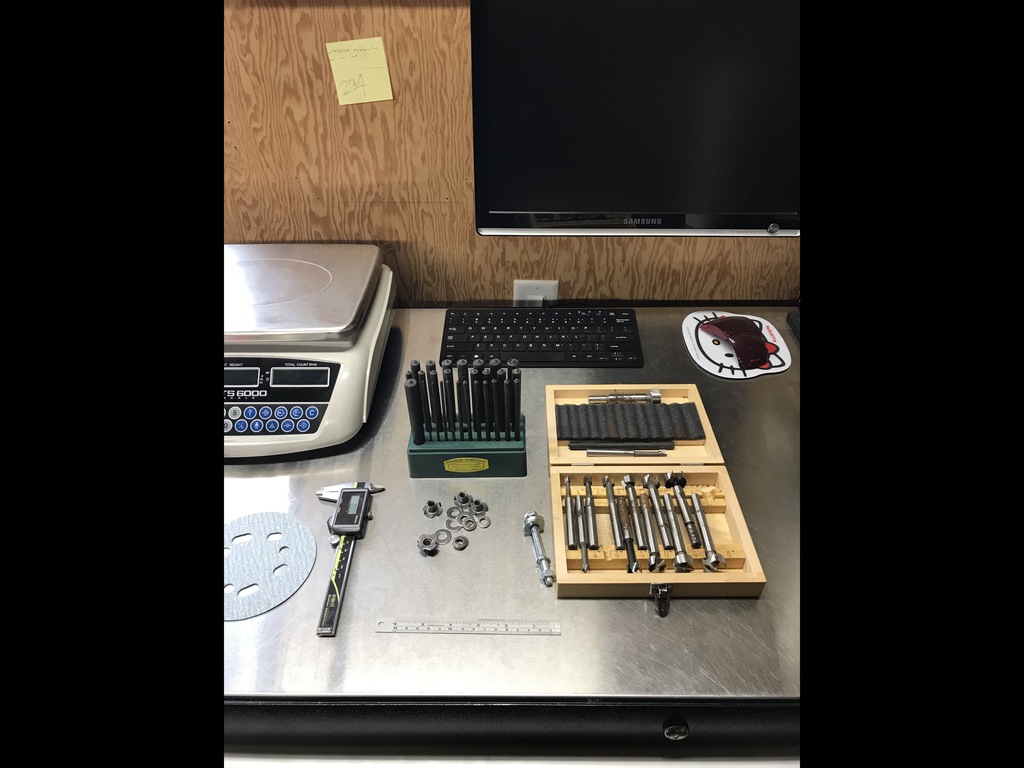

If you true bicycle wheels using indicators, dial or digital, you’ll know the joint area can be problematic on some rims. A little twist or bump can wreak havoc, sending your instrument to the moon if only for a moment. It’s possible to work around this problem.

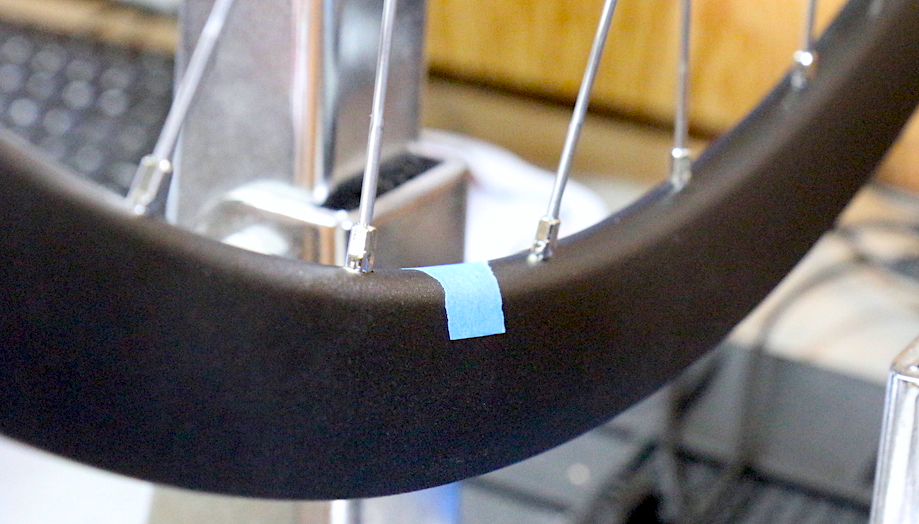

Normally truing is oriented from the valve hole, starting at the valve hole and continuing around the wheel until returning to the valve hole again. It’s nothing special other than being a signpost to indicate you’ve covered the whole wheel. Instead start at the joint. Begin scanning immediately after the joint and continue around the wheel until returning to the point immediately before the joint. This factors out hyperlocal distortion at the seam. If you need to make the joint more conspicuous, apply a little piece of masking tape to establish your own signpost.