In stand dishing

October 1, 2023

Islandix customer Toby sent this video saying it helped him understand in stand dishing (centering). Thanks to PSIMet for posting it.

The first part of the video talks about inserting the wheel in the truing stand the same way each time taking special note of the axle orientation. The second part of the video demonstrates a deliberate way of using the truing stand — how the wheel is removed, flipped and re-inserted. It’s notable he doesn’t loosen the truing stand uprights at all, preferring to spread them against the builtin spring. Altogether the message is consistent measurement is important for maximum accuracy.

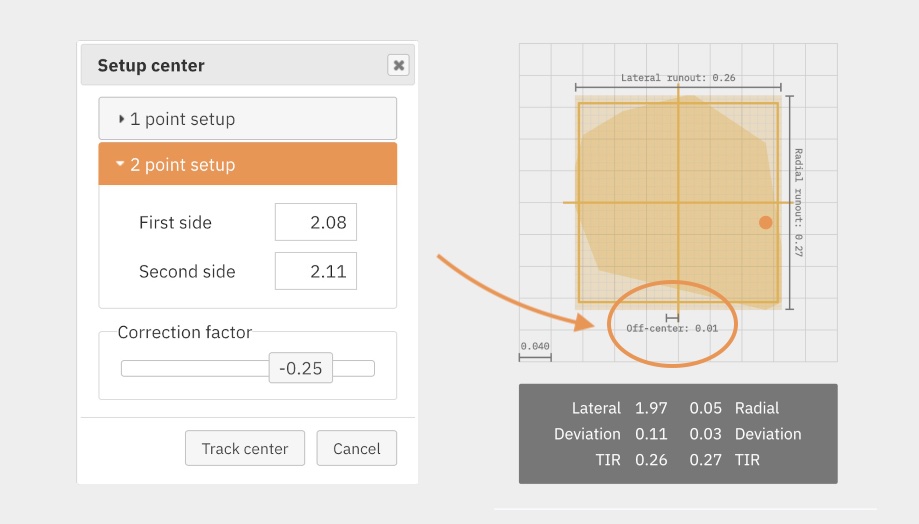

Islandix dishing with the Target Plot works the same way except there’s no need to adjust the indicator to zero since software takes care of it. The software is simple. It records two measurements and computes two facts: the difference between the measurements and the direction (for example the rim is dished 0.3mm to the left).