I have a prebuild ritual that involves quite a lot of inspection. It’s a simple process — I look over everything deliberately and see if anything stands out. I’ll pay attention to the rim stickers and hub branding so their orientations can be chosen deliberately.

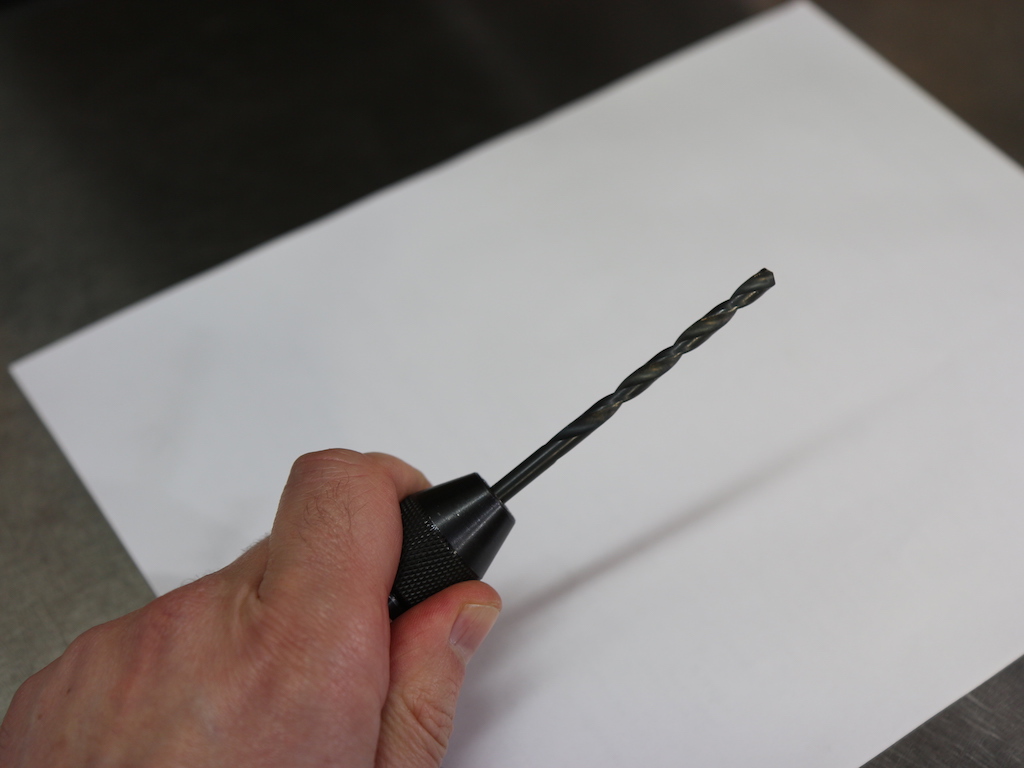

On alloy rims I like to visit every spoke hole with a chamfer tool or a handheld drill bit. This puts a subtle profile in the hole where the head of the nipple rests. Sometimes there can be a coil of drilling chaff attached to a spoke hole — a chamfering pass breaks them off and smooths any burrs. When I visit the joint I look at the internal sleeve, if any. Does it interfere with nipple fit?

Measuring is inspection

Measuring your own ERD can indicate a lot. Use the measuring step to dry fit washers if using them. Do the washers sit nicely in the rim? Measuring will tell you if your rim is round or oval. All else being equal the rounder the rim, the better the result in terms of alignment and tension balance. If your rim is oval, expect to spend a little longer at the bench to reach perfection. Have you ever found a job difficult and doubted your skills? It could be the rim.

Published February 29, 2020