Industry Nine fat wheels

December 17, 2018

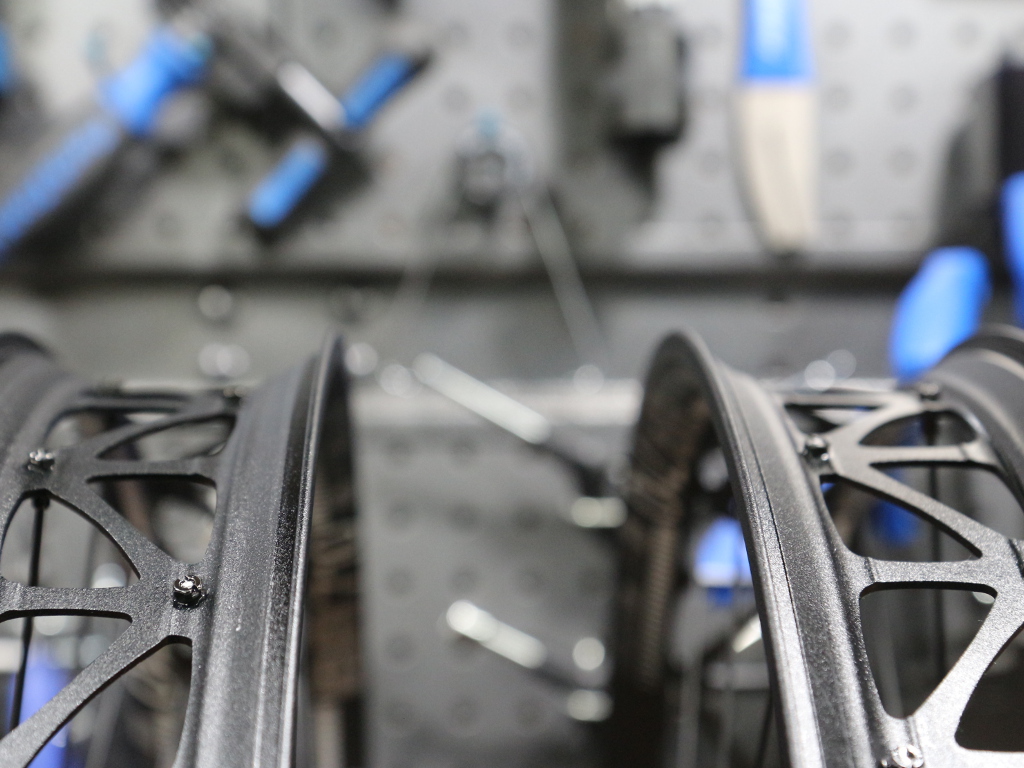

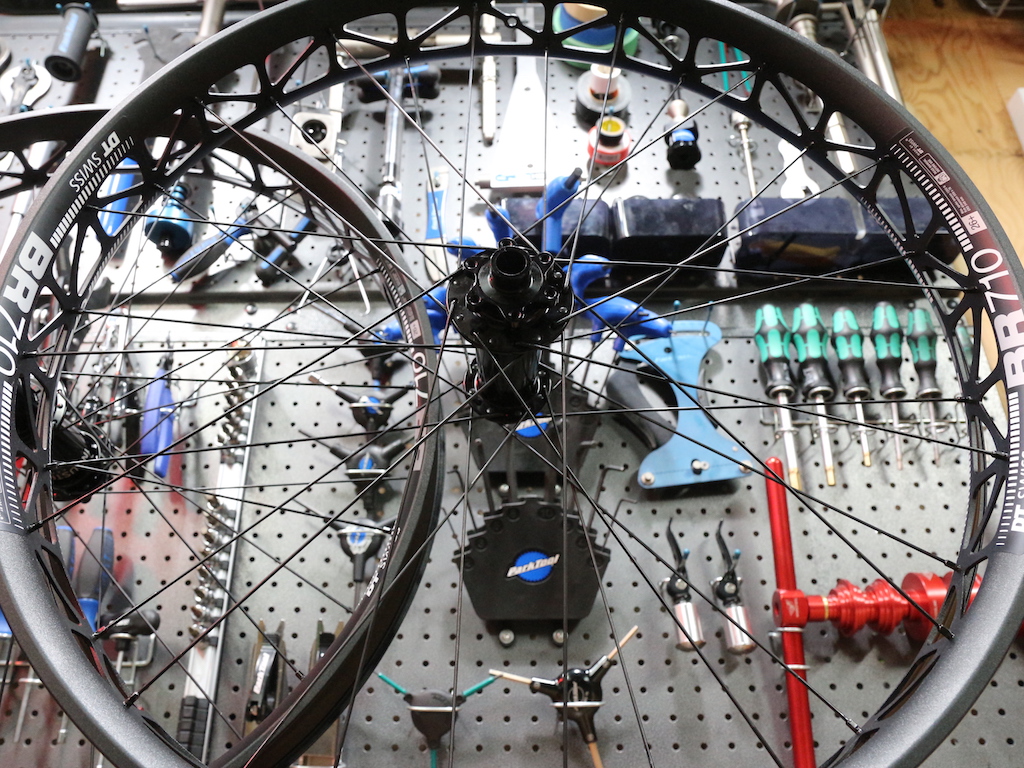

Some parts of Canada call for a different approach to winter riding. These wheels are the full fat approach, marrying Industry Nine fat hubs to DT Swiss BR710 rims. The hubs are 142×15 in the front and 177×12 in the rear.

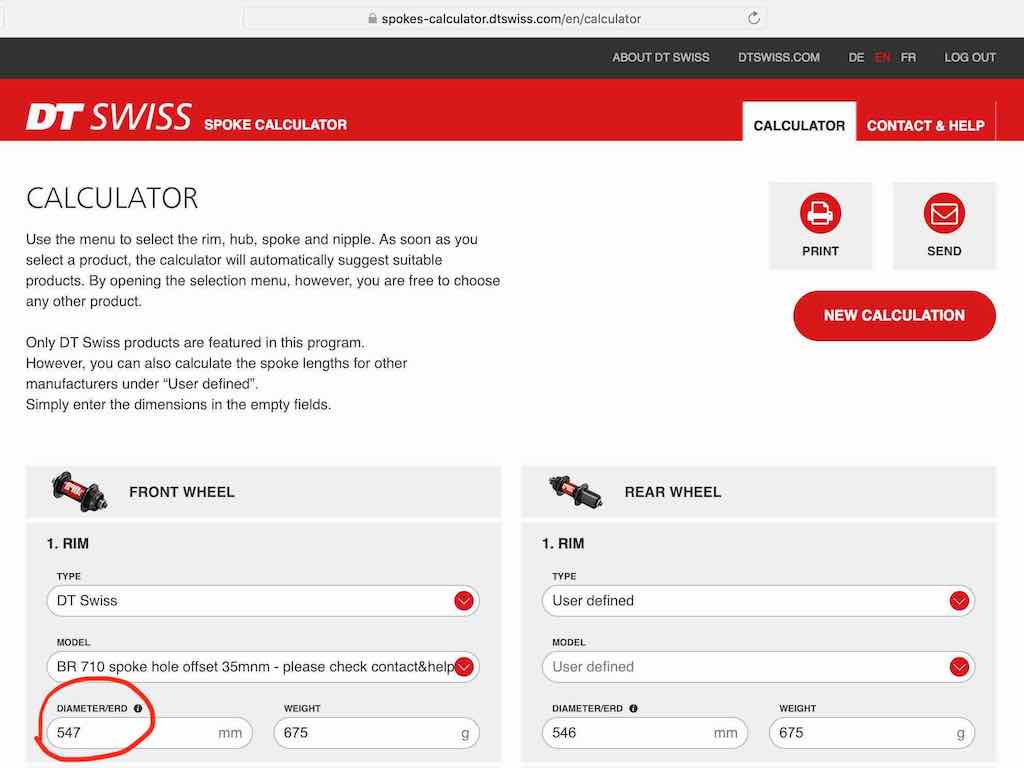

Spoke length

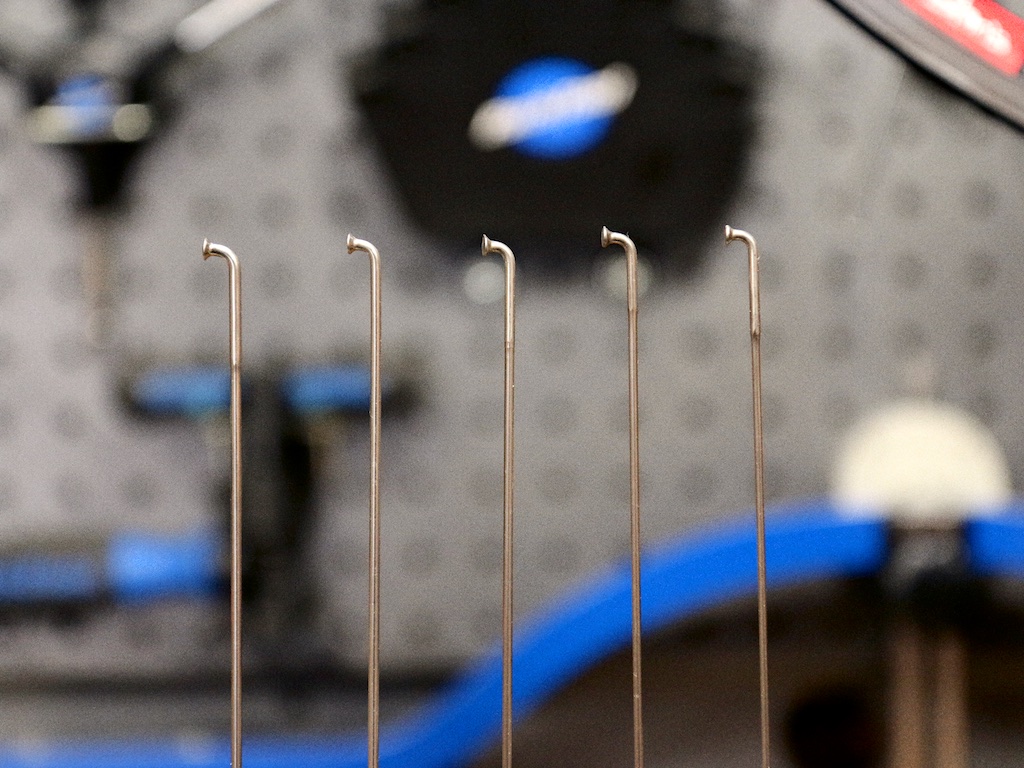

These rims are a good example of ERD issues discussed in my last blog. The DT Swiss rim decals include technical information stating ERD to be 549mm. I like that but it doesn’t change my process — I measured them anyway getting 547 on the front and 546 on the rear. To add intrigue the DT Swiss spoke length calculator lists 547 for this rim. Going my own way resulted in perfect penetration, a hair below the top of the nipple in each case. With single wall rims you want to be more fussy about spoke length, particularly avoiding penetration past the top of the nipple.