Campagnolo road

December 31, 2015

Super attractive wheels: White Industries T11 hubs to H Plus Son Archetype rims. With DT Revolution spokes and alloy nipples, total wheelset weight is 1560g — light yet strong.

Super attractive wheels: White Industries T11 hubs to H Plus Son Archetype rims. With DT Revolution spokes and alloy nipples, total wheelset weight is 1560g — light yet strong.

This build is White Industries T11 hubs laced to Stan’s Alpha 400 rims; Sapim D-Light spokes on the front and a blend of Sapim Race and Sapim Laser on the rear. 1518 grams total.

I’m often asked what adapter spacers to use when mounting different road cassettes. The answer depends on your freehub and cassette. If you’re a Campagnolo user, the good news is no spacers are required if you’re using 9, 10 or 11 speed cassettes.

Shimano is more complicated. Shimano-compatible freehubs utilize the same design for 9 speed and 10 speed (ignoring the special outlier case of Dura-Ace 7800 hubs). If you want to run 9 speed with such a hub, no spacers are required. If you want to run 10 speed, a single 1mm spacer is installed behind the cassette. This spacer is packaged with 10 speed cassettes.

When using 11 speed Shimano-compatible hubs with 11 speed cassettes, no spacers are required. 11 speed hubs are backwards compatible with 9 speed when a single 1.85mm spacer is installed behind the cassette. To run 10 speed, install the 1.85mm spacer in combination with the 1mm spacer (2.85mm total). The 1.85mm adapter spacer is usually packaged with 11 speed hubs — if you’re missing this spacer and need one for compatibility, email and I’ll sort you out.

My third Rohloff build in the last year was just completed.

Blacked out wheels. DT Swiss 350 hubs laced to H Plus Son Archetype rims.

In 2015 I don’t recommend carbon clinchers for rim brake applications. Carbon clinchers for disc brakes are a different story. Check out this recent build of carbon rims to Hope hubs:

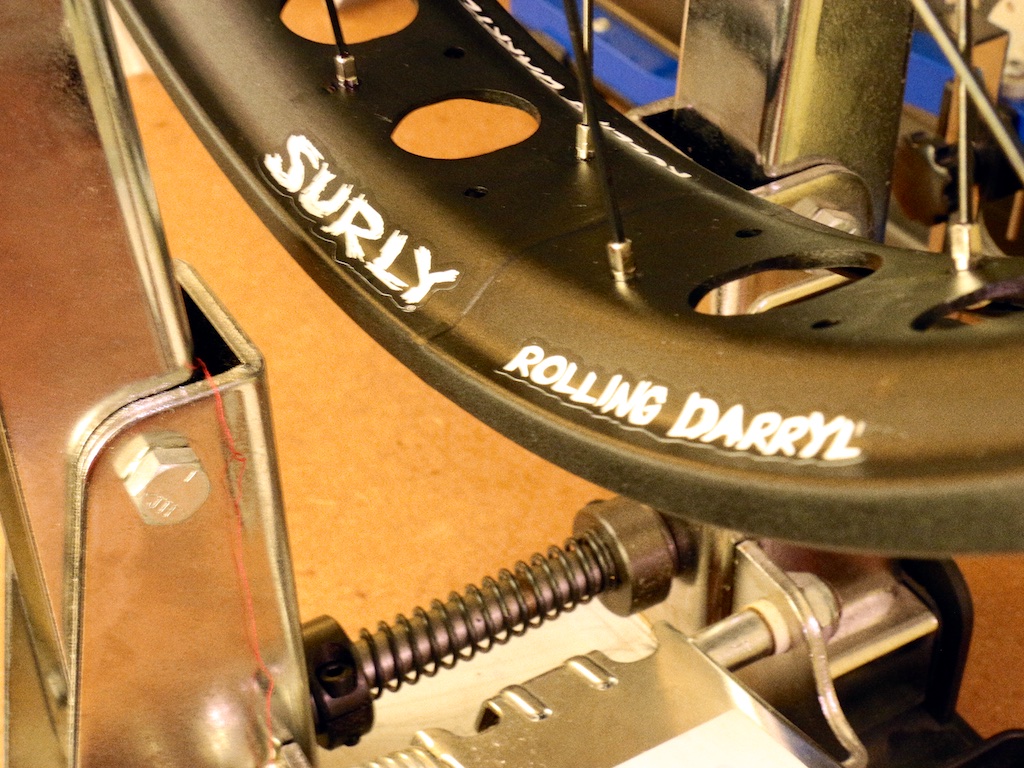

This year I’ve built two sets of Rolhoff wheels using different models of Surly fatbike rims. Coincidentally both wheelsets are headed for epic adventures in Australia: the first set is headed for Tasmania and the second to the Canning Stock Route in Western Australia.

Stan’s Grail is a wider road rim for disc applications. A recent build:

This everyday wheelset mates classic-looking White Industries T11 hubs and Stan’s Alpha 400 rims. These rims build light wheels and offer the option of running tubeless or with tubes. With 28 DT Competition spokes per wheel and brass nipples, they’ll be rock solid for years.

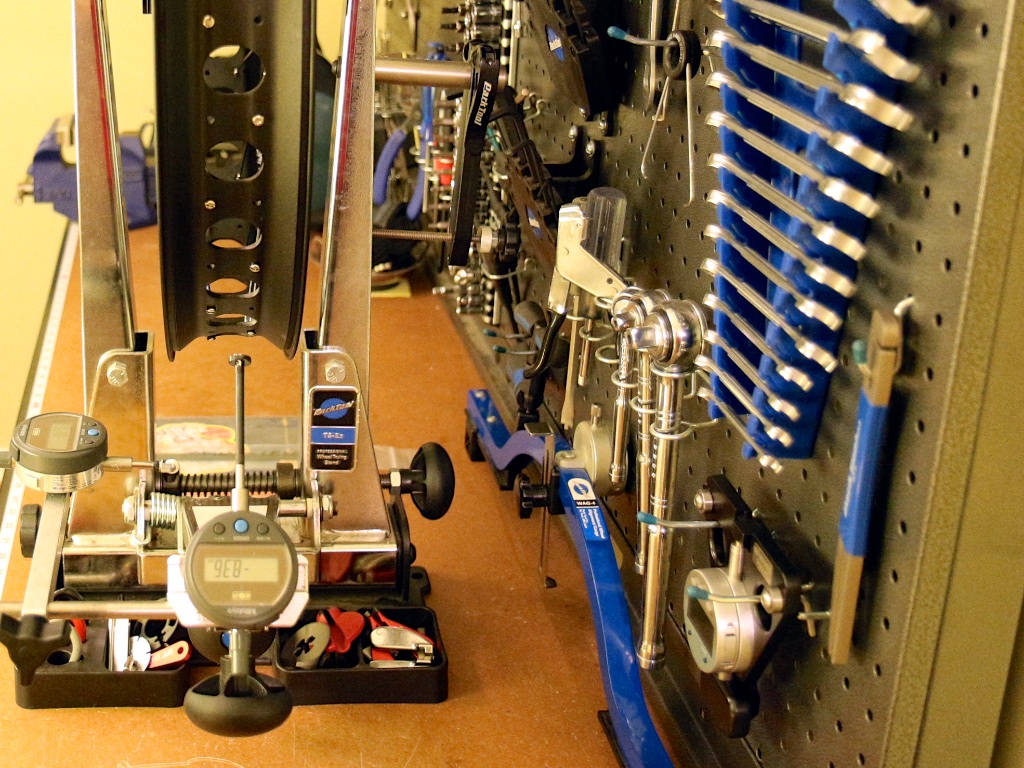

A few times a year I get a query about the digital dishing tool I’ve shown online. It’s something I came up with myself though I’d be surprised if I was the first.

You’ll recognize the base tool as the standard Park Tool WAG-4. It’s a decent tool with sliding blocks that lets you check dish even with tires mounted. Checking dish with the analog indicator probe is fast and easy. The problem is it’s not quantitative. I record a ton of stats about every wheel including tension at every spoke and three kinds of alignment. To record dish alignment with a conventional tool you need feeler gauges and that’s a bit cumbersome.

I had a spare digital gauge in my toolbox so I mounted it up with no fuss. The lug back on the gauge can rotate 90° so I oriented it perpendicular to the shaft. I re-used the existing hole on the WAG-4 so no drilling required — I simply removed the existing screw and replaced it with a slightly longer one to accommodate the thickness of my gauge mount plus a washer. It’s a wood screw and I was able to find a longer one of the same diameter and thread pitch at Home Depot. That’s it.

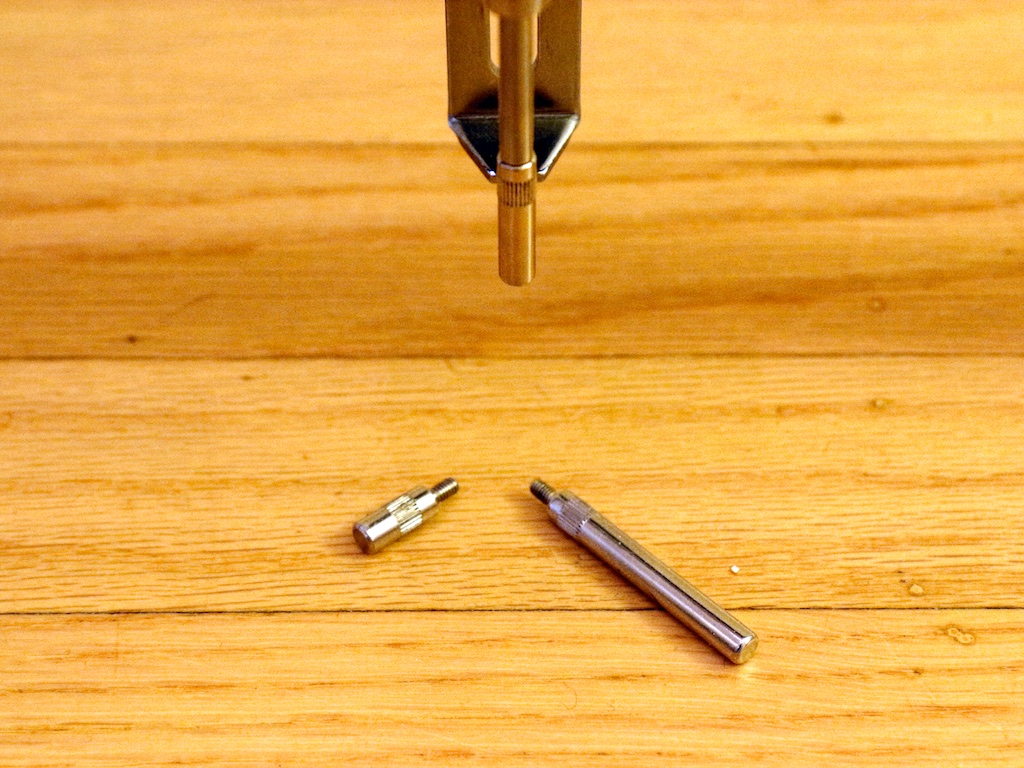

The issue with my gauge is the throw of the indicator — the range isn’t appropriate for all axle lengths. I could find an indicator with more throw but this was a project done on the cheap (the cost of a screw if you discount the bits on hand). I deal with this problem by installing indicator contact points of different lengths, suitable to the axle in question. Actually I do gross dishing using the regular analog probe and then install the correct tip to record final dish. When using the regular probe it’s handy to remove the contact point altogether so the digital indicator is out of the way.

How does it work? Pretty well. Having the accuracy of a digital gauge makes you realize the limitations of the underlying tool. I balance the digital dishing tool over the wheel and hold it with the lightest touch otherwise the tool flexes and tilts, distorting values. This amount of distortion wouldn’t lead to bad wheels but it doesn’t hurt to sweat the small stuff if you’re bothering to measure.